A fountain pen brings respect and ritual to a simple daily task: writing. By filling it with ink, using varying line weight, and investing in a quality pen, it can become a part of one’s personal style.

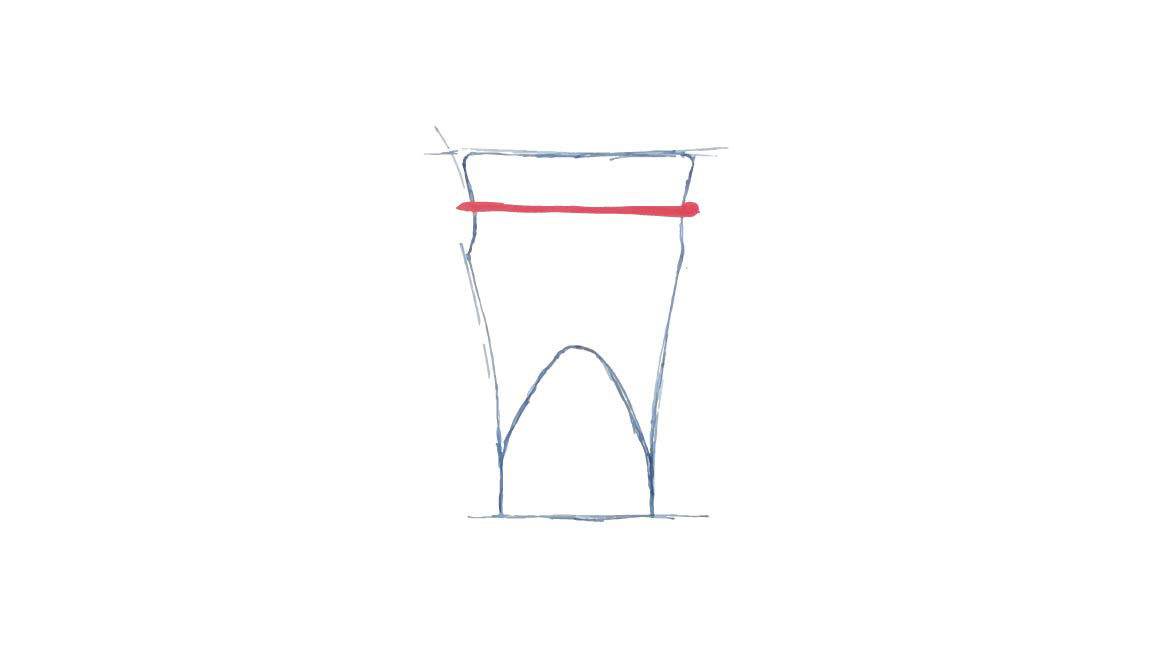

I tasked myself with creating a fountain pen casing from only metal, complete with a threaded cap and section.

Ideation. Core idea: a sleek segmented body with a flared cap, with a subtle pocket clip.

However, there was no tubing thick enough to accommodate threads.

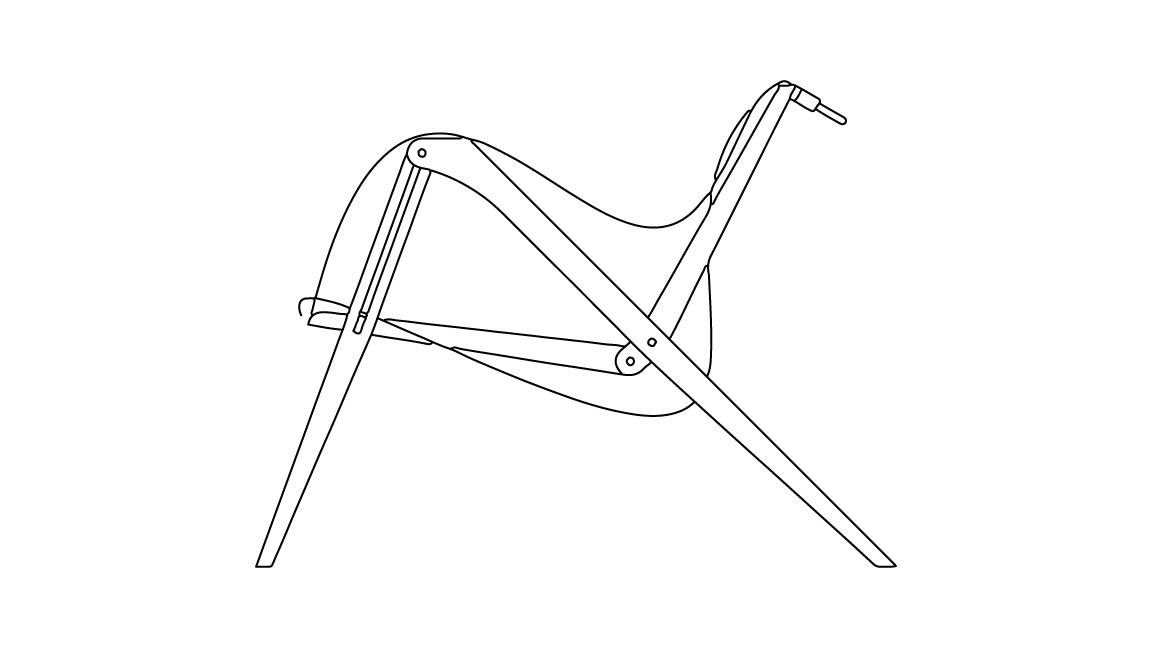

Tubing had to be created by bending a rectangular sheet over a cylindrical die, and then threaded.

All of these tubes were cut from a sheet, formed with a die, and soldered closed.

Then, the appropriate sizes of taps and dies were used to put threads on the end of the body and on the inside of the cap.

None of them were successful. Each tube changed sizes after being heated and cooled during soldering, and could not be threaded accurately.

At this stage, threads were out of the question.

A new system was devised using tubes that nested and fit together with friction.

Using prefabricated parts and tubing ensured that every part fit correctly and the function of the pen was not inhibited.